At present, there are mainly three types of clean vegetables on the market: high-quality vegetable clean vegetables, fresh-cut ready-to-use vegetables, and fresh-cut ready-to-eat vegetables. Vegetables are processed into clean vegetables before they are put on the market, which can not only dispose of kitchen waste in advance, but also provide consumers with options with higher utilization rate. As garbage disposal becomes stricter and labor becomes more expensive, large chain companies will use their own central kitchens to directly deliver ingredients. The use of ready-to-use clean dishes by other catering companies will become more and more trendy. For the vegetable washing processing line, what are the main application scenarios?

1. Vegetable cleaning and drying plant

The vegetable washing and drying processing plant mainly produces high-quality vegetable clean vegetables, and cleans, air-dries, and packs vegetables. Although the most basic clean vegetables are processed, the products are the mainstream of the clean vegetables industry today. As a consumable such as clean vegetables, the daily market demand is large.

In terms of input, vegetable washing and air-drying processing plants only need conveyor belts, small farm vegetable washing equipment, air-drying equipment, and packaging equipment to carry out processing and production. The requirements for the area of the factory are not strict, and it is a production mode with little investment

2. Central kitchen vegetable washing processing

The central kitchen is a centralized large kitchen with complete functions, specializing in the production of large quantities of fast food, and then delivering the fast food to the units, companies, enterprises and canteens in need. The smallest central kitchen can serve several thousand people, and the larger central kitchen can serve 150,000 to 300,000 people.

The central kitchen vegetable washing processing line system is a set of automated production processes that specialize in processing fresh and clean vegetables. The central kitchen vegetable processing line arrangment processes the vegetables that serve hundreds of thousands of people a day, mainly including leafy vegetable washing line and bulb vegetable washing processing line.

3. Processing of prefabricated vegetables

Pre-prepared dishes are convenient dishes that can be eaten directly by means of modern standardized assembly operations, preparatory work for the raw materials of the dishes, simplified production steps, hygienic and scientific packaging, and then heating or steaming. Consumers want to find a balance between busy work and cooking, which can ensure the efficiency of cooking, but also ensure that the food is safe and hygienic. Pre-made dishes just meet people’s needs, save the cumbersome process of washing and preparing vegetables, not only save time and energy, but also provide high-quality protein food. According to expert analysis, prepared dishes will have the potential to grow into a trillion-level market in the future.

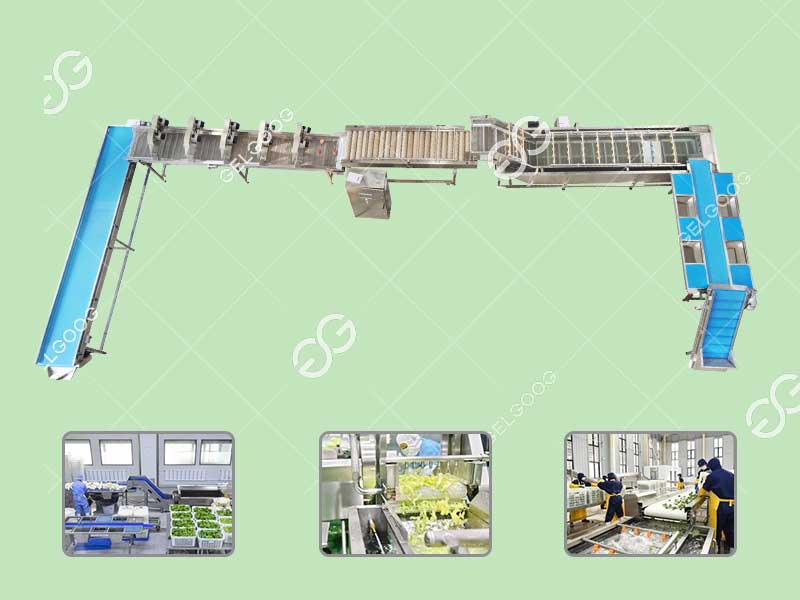

The vegetable washing processing line is a complete set of vegetable washing processing line newly designed and manufactured by our company after years of practice, introducing advanced design concepts of foreign vegetable cleaning processing, and combining with many successful domestic vegetable cleaning processing examples. And according to different production raw materials, there are leafy vegetable washing line, leafy easy-cleaning vegetable production line, easy-cleaning vegetable sterilization production line, root vegetable cleaning production line, etc., suitable for all kinds of factories, school canteens, central kitchens, and assured breakfast. Engineering etc. At the same time, our company can provide full-process services such as workshop equipment layout, customization, installation and commissioning according to the customer’s production scale and process requirements.

If you want to invest in a vegetable washing processing line, please leave a phone call or leave a message, we will contact you as soon as possible, and work together to build a broad platform for business success.